Mampaey Offshore Industries provides tests before delivery of all products. They assure that the product complies with the applicable classifications and the standards. All tests are performed in close cooperation with our customers and witnessed by a third party (classification authority) surveyor if requested.

Classifications products:

Services

To inventory the local requirements Mampaey Offshore Industries performs site checks.

We also perform a complete multidiscipline analysis of the intended use and specific integration needs.

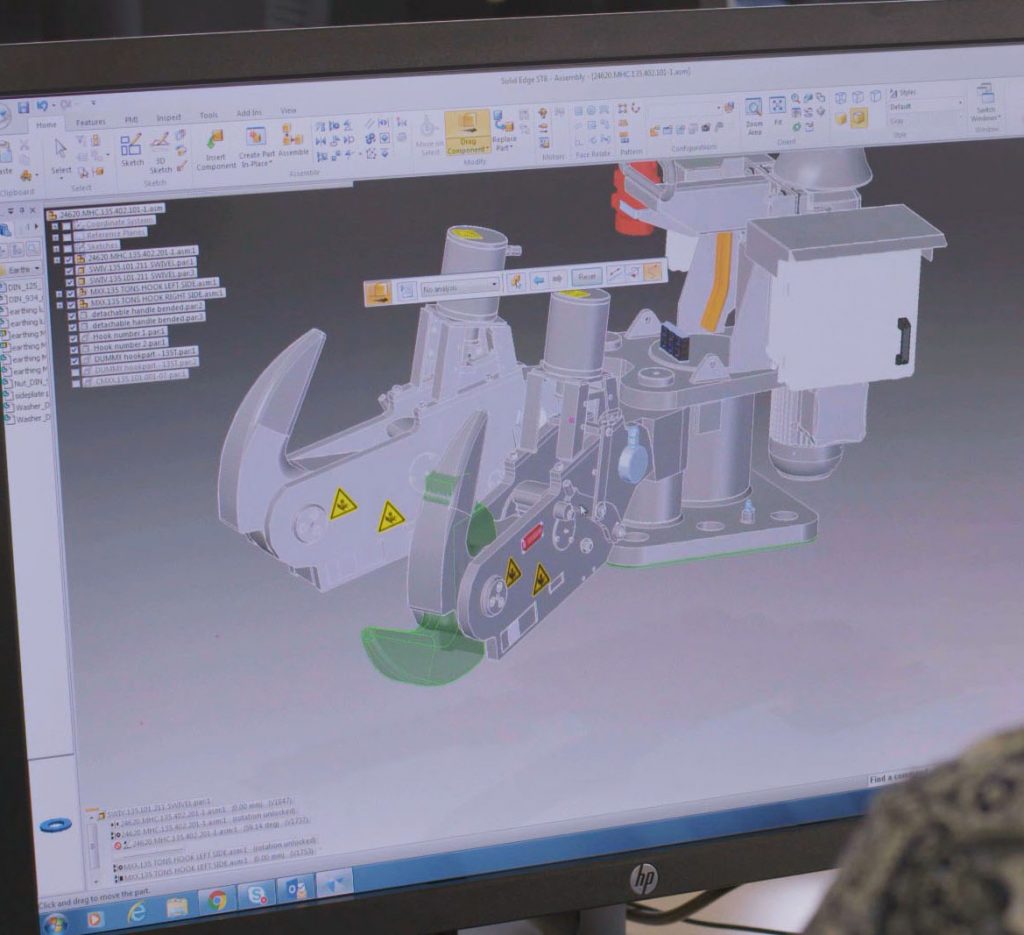

Design & Engineering for towing, berthing and mooring

Research & Development are important to us

Production & Quality

To ensure the quality of our products we take certain measures. We want to meet the demands of high duty cycles and severe offshore and environmental conditions. Therefore Mampaey Offshore Industries manufactures all equipment within her own product line of certified material.

We want to ensure and enable traceability, so all load/stress parts are stamped with the heat number of the main raw material. This heat number can be found on the material certificate. In this way the end-user is sure that with registration the quality of every individual hook part is guaranteed and traceable.

Our product life time is 25 to 30 years. This established through our state-of-the-art engineering, design and manufacturing process. If the prescribed maintenance schedule is followed, longer product life can be achieved.

Testing & Certification

- Load Testing

- Factory Acceptance Test (FAT)

- Site Acceptance Test (SAT)

- Certification ATEX/ IEC Ex

- Certified Production Process

Commissioning & Training

Mampaey Offshore Industries ensure proper startup and integration of the equipment into production facilities with our commissioning services. Our service engineers routinely work on similar equipment so they are knowledgeable and skilled in every facet of the operation and maintenance of our systems.

We offer an onsite training where operators, maintenance and IT personnel can learn to operate the equipment in a safe manner. In addition to the basic operating procedures, our service technicians provide the necessary information, including:

- How to perform routine preventive maintenance

- Troubleshooting problems

- Ensuring that equipment functions with minimum down time

- Enabling a long life cycle.